Your current location:

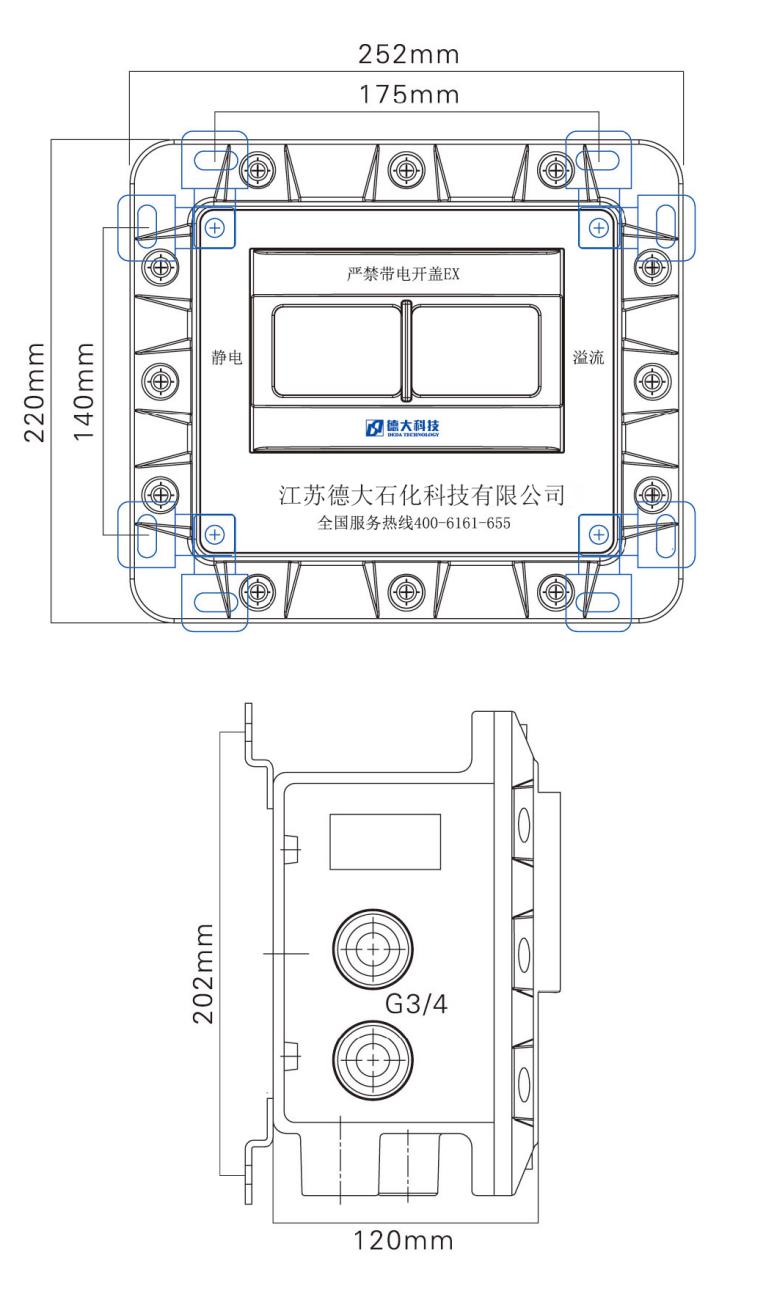

Dyj-d type oil spill electrostatic controller

The dyj-d oil-spill electrostatic controller (top mounted) can effectively prevent the overflow in the process of liquid filling. At the same time,it ensures that the resistance of the electrostatic discharge circuit between tank truck and ground pile conforms to the relevant safety standards.

System composition and functions

The dyj-d overflow electrostatic controller (top mounted) is mainly composed of the main controller, DSC electrostatic ground clamp, DOP explosion-proof sensor, DG reset board and ground wire, etc.

1. Main controller

1. Main controller

A. Detect the liquid level signal of DOP explosion-proof sensor and the signal of DSC electrostatic ground clamp;

B. Detect the homing sensor signal of the system and crane pipe homing sensor;

C. Drive the acoustooptic alarm to issue the acoustooptic alarm signal;

C. Output switch volume signal to the oil payment system;

2.DOP explosion-proof sensor

2.DOP explosion-proof sensor

A. Optical principle, integral safety design;

B. Convenient installation and adjustment, and the alarm height can be adjusted by locking the positioning device;

C. Wide input voltage range, full digital circuit design, strong anti-interference capability;

D. The standard distribution cable is 7 meters long (the cable length can be customized).

E. Explosion-proof tuning fork liquid level sensor is optional

3.DSC electrostatic ground clamp

A. special cemented carbide top;

B. Break the paint and remove the rust to ensure the car body is well grounded;

C. It can be equipped with 5 m PU straight line or 7 m PU spiral line (1 of 2 choices).

4. DG place plate

4. DG place plate

Whether static electricity ground clamp is reset after use is the basis of standby status of the system.

5. Ground wire

5. Ground wire

A. Introduce static electricity from the car body into the ground to ensure the generation of static electricity equipment

Safe ground;

B. The standard distribution cable is 3 meters long (length can be customized).

6. Crane tube homing sensor (optional)

6. Crane tube homing sensor (optional)

A. Collect crane pipe attitude and chain hair oil to ensure crane pipe is inserted into the tank car;

B. Interlock gear and other equipment to prevent the crane pipe from being torn off;