Your current location:

Page view:

Dyj-k anti-overflow controller

I want to make an inquiry

Product introduction

Technical Parameters

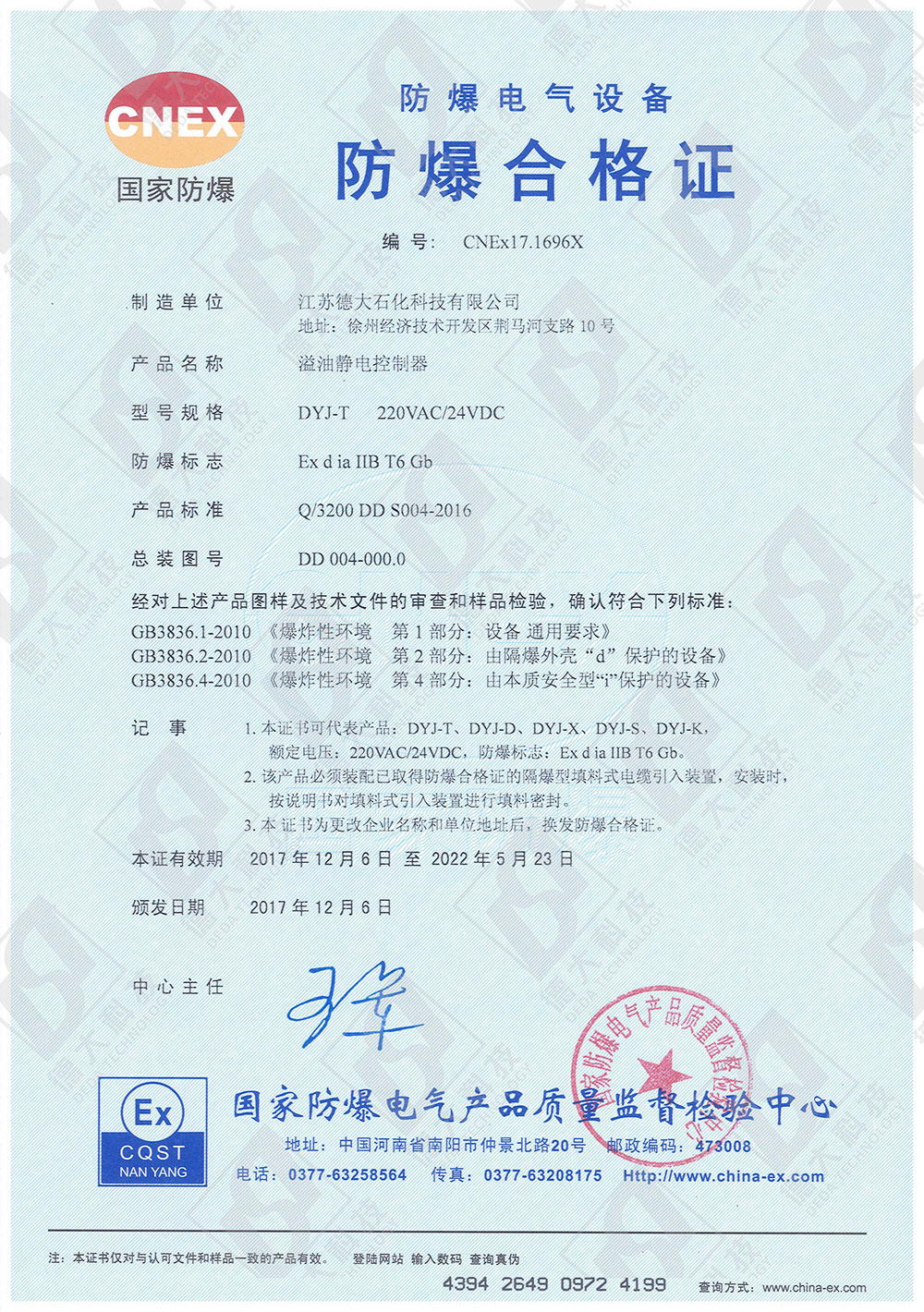

Explosion-proof certificate

Using range

Dyj-k anti-overflow controller is designed for top petrochemical product loading and unloading. The system detects the liquid level signal through the DOP explosion-proof sensor. When the liquid level exceeds the set alarm position, the equipment will sound and light alarm, and at the same time output the relay switch volume signal for oil payment and other loading and unloading system control.

Especially suitable for liquid petrochemical products with frequent turnover, such as inflammable and explosive, etc., such as:

1. Fuel oil loading system (including railway tank car and road tank car);

2. Sealed loading of liquid benzene and hydrocarbons;

3. Filling system of other chemical products;

System composition and functions

Dyj-k anti-overflow controller is mainly composed of main controller and DOP anti-explosion sensor.

1. Main controller

1. Main controller

A. Detect the DOP explosion-proof liquid level sensor signal;

B. Drive the acoustooptic alarm to issue the acoustooptic alarm signal;

C. Output relay switching signal to loading/unloading system such as oil payment;

2.DOP explosion-proof sensor

2.DOP explosion-proof sensor

The DOP explosion-proof level sensor USES optical principle to detect the liquid level in the loading and unloading tank truck

Situation. It is bundled with crane tube mounting to the main controller

Provide liquid level signal, realize linkage control with loading and unloading system.

A. Optical principle, integral safety design;

B. Convenient installation and adjustment, and adjustable alarm height through stainless steel clip positioning device;

C. Wide input voltage range, full digital circuit design, strong anti-interference capability;

D. The standard distribution cable is 7 meters long (the cable length can be customized).

E. Explosion-proof tuning fork liquid level sensor is optional

Previous article

Dyj-d type oil spill electrostatic controller

Dyj-s antistatic controller

Next article