The metering loading system is an automatic quantitative oil delivery system that is composed of a host computer, which is applied to send control commands, metering loading controller, and other loading equipment, such as pipeline pump, flow-meter, control valve, electrostatic overflow controller, explosion-proof LED display.

With the comprehensive implementation of industry 4.0 and China's intelligent manufacturing 2025, the world will enter the fourth industrial revolution dominated by intelligence. Petrochemical storage and transportation management system through years of practice and continuous innovation to upgrade, I company has formed a management system for intelligent transportation loading and unloading, again tie-in developed self-help quantitative loading system, the company can achieve fuel in the tank farm, the entire intelligence in big data analysis, improve the efficiency of transportation, pay oil accurate rate and weighing calculation accuracy, reduce staff error, cost savings, improve the economic benefit.

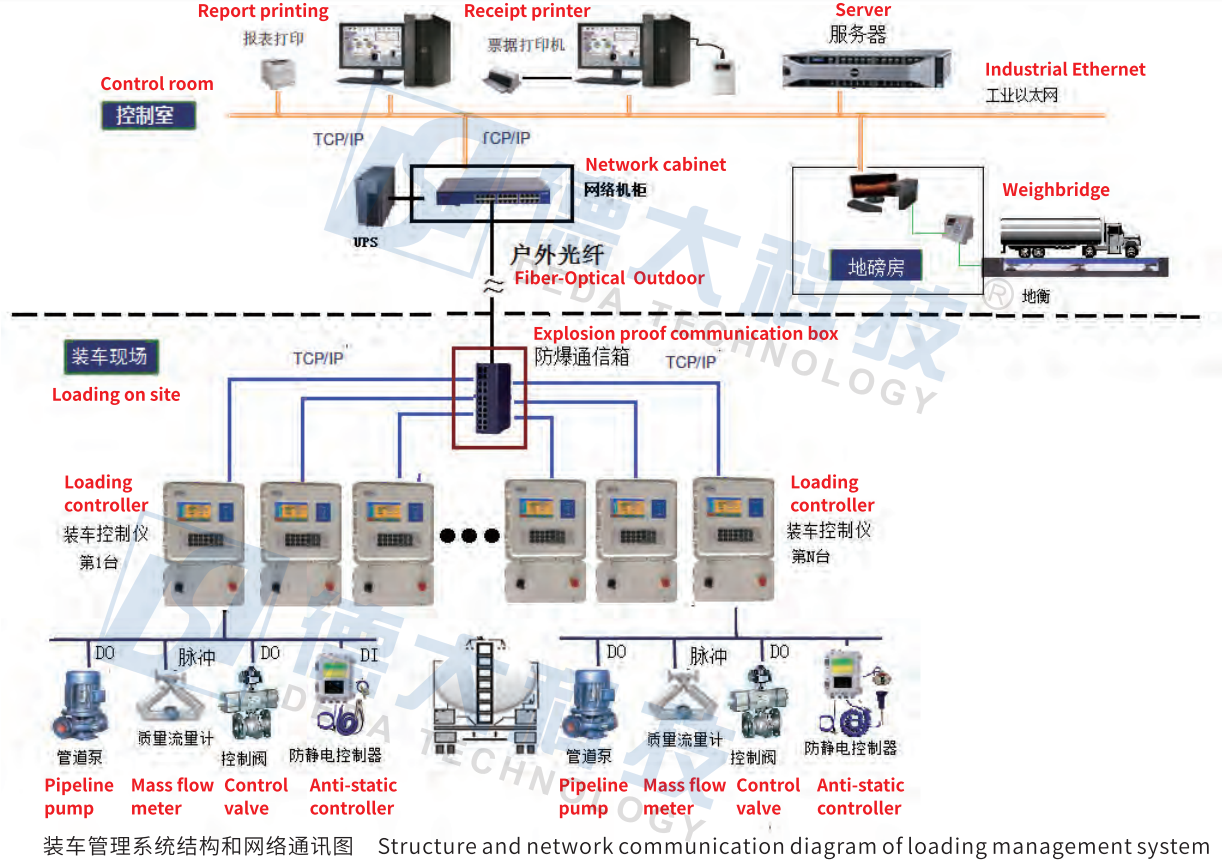

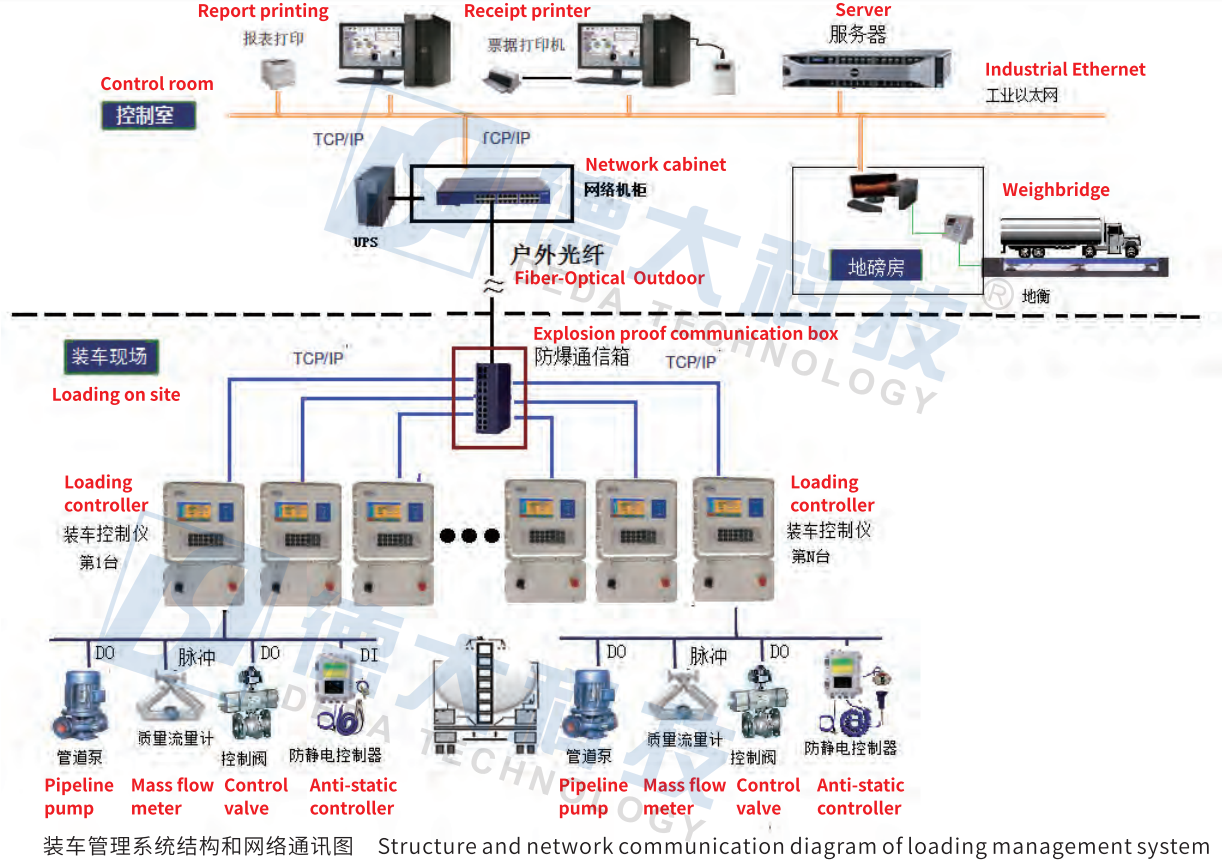

System architecture description

1. The process of the intelligent storage, transportation and loading system mainly includes: business management, management of the access plant, self-measurement and quantitative loading. Through the closed-loop linkage of all business processes, the overall management of intelligent storage and transportation is upgraded.

2. The business segment includes two functional modules, sales order management and vehicle information input, to prepare the vehicle for oil loading in the factory.

3. The process of entering and leaving the factory covers the driver's queue for getting the card, the driver's security check, and the vehicle's access control power module, which helps the vehicle enter the factory in an orderly and efficient manner and ensures the safety of the tank area.

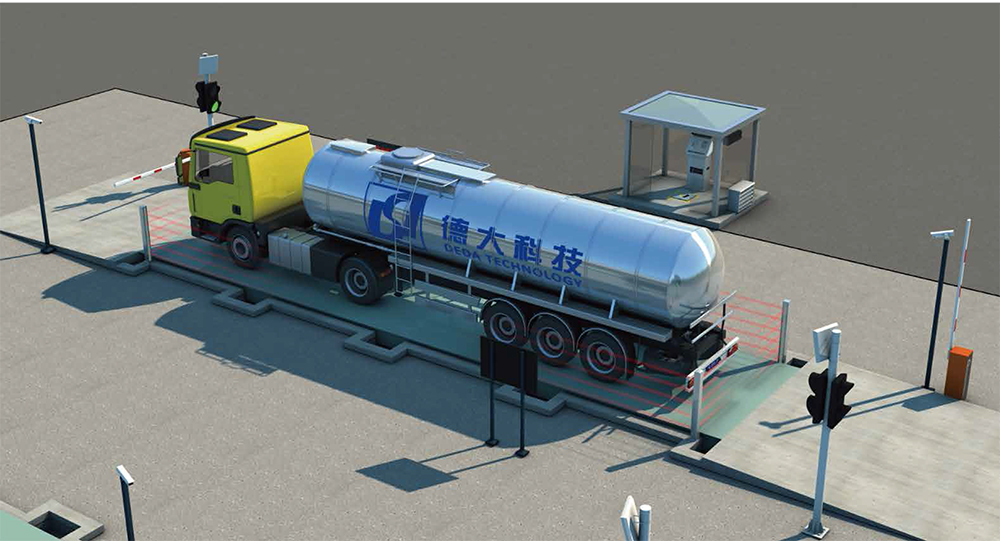

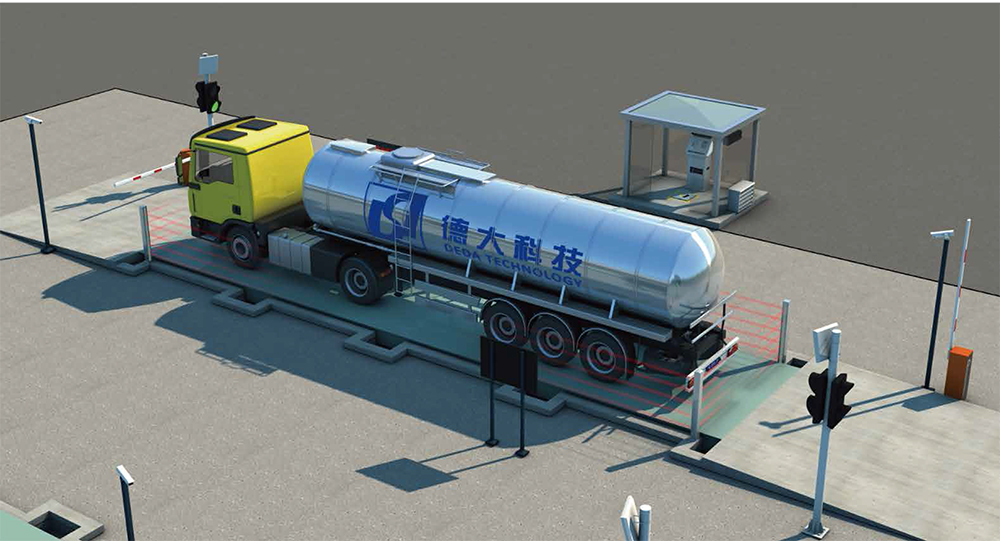

4. The self-measuring links mainly include the floor weight and the self-measuring terminal. The car number recognition camera, R FID card reader and environment camera are installed on the ground weight to avoid cheating.

5. The intelligent storage and transportation system connects with the quantitative loading system and realizes the automatic starting and stopping of the quantitative loading system through IC. Ensure accurate and efficient oil payment.

1. The customer makes an appointment to pick up the goods on the purchase platform. The pick-up vehicle arrives at the parking lot of the oil depot area.

2. When the company's machine enters the hall, brush the id card on the self-service card pickup terminal, confirm the information of the vehicle and goods collection, and get the IC card. The large screen of L ED displays queue number and other information, waiting to go to the loading and unloading area

3. When the division machine arrives at the gate post of the loading and unloading area, the R FID card reader and the vehicle number recognition camera simultaneously read the vehicle information. After verification, the vehicle enters the storage area. Vehicles enter the weighing area, car number recognition camera license plate number, no mistake, the green light is bright, the vehicle through the ground sense coil entrance gate open, vehicles on the pounds, the infrared light curtain automatically detect vehicles set, vehicle completely on the pounds after the lights turn red, R FID card reader automatic extraction and identification of vehicles information and taken as, without by accident, the driver of the car to the move said heavy machine before the final end, standing on one body said the car tail fell under the way of the gate, brush machine IC card, After the weight is weighed, it shall record the weight of the weight, record the weight of the weight and record the weight of the weight after the weight is recorded and the weight is shown.

4. The driver drives the car to the crane pointing. Release the static electricity of the human body, connect the static electricity overflow controller and install the crane pipe at the bottom, then brush the IC card on the fixed volume vehicle control device with the brake drop bar, and confirm the information. When the fixed amount of oil payment is set, the system will stop the pump, close the valve, and bundle the car

5. When the vehicle enters the weighing area, when the vehicle is weighed, the company will brush IC card in front of the end machine of self-balancing weight, record the gross weight system, print the weight sheet, and go to the general hall of yingye to handle the processing and calculation of business affairs, issue the goods invoice and return the IC card. Menweigen was confirmed to be free by invoice.

I. business management

The business circle section includes two functional modules: sales order management and vehicle input. The platform supports PC end and mobile end to ensure the business spirit. Sales order: maintain customer name and material information, including basic information such as single price, order quantity and floating amount; Vehicle management: input basic information package including vehicle information, company information (name, phone number, id card number), invoicing volume (order quantity), etc.

Through the sales platform, the purchaser can check the oil product information, make pick-up booking and advance payment. The data center processes orders and sends instructions to the business processing window. When the vehicle enters the tank area, the driver enters the license plate number and mobile phone number to verify the pickup information, receives the verification code, takes out the queue size, and prepares the business card printing.

Sales order management

Sales order management link can be connected with e-commerce, finance, ER P system, customer order, contract, etc. The system order module itself supports the management capability of concord/order, the basic data such as BOM management and merchant management, etc., so as to order the single closed loop flow control, connect with the subsequent intelligent loading system, guarantee the intelligent storage and operation management of oil products, reduce the human intervention in the process of storage and transportation, and avoid the error.

Vehicle entry

The entrustment management part supports the docking of the third-party logistics system, and the system itself supports the management of the entrustment of customer and business commission and the registration of car number matching: the registration of car number matching shall be entered by the business personnel in line with the registration of car number matching, so as to ensure that the entrustment requirements of car number of large and small customers can be met.

Ii. Access management

Self-service card introduction

The end of the self-issued card is the equipment integrating information and intelligence energy collection, card output, data management, card verification, etc., with strict management, efficiency improvement, rational use of resources, information and interest sharing, etc., which is an in-depth embodiment of the construction of information and information of intelligent energy. Since the end of issuing the card, the root issued a request to the data system of the machine room according to the information of the machine body certificate of the company. In the data, the center adjusted the loading oil signal and the machine check.

Queuing call introduction

The function of queuing and calling is to replace the traditional way of standing in line of customers in various service Windows, and the computer system will replace the customer queuing. Our company upgrades the usual line of calls. After the user gets the card, the crane position queue management is carried out through the crane position matching material name, 1 vehicle 2 standby mode (which can be set up from the bank). The system can inform the driver to check the car into the factory by L ED and external acoustic column.

Advantage is introduced

It is scientific and reasonable to have automatic queuing system

Parliamentary L ED large screen display, voice broadcast, text message reminder triple guarantees to prevent errors

The system automatically matches the waiting vehicles to select the crane position to improve the efficiency

The system will set the vehicle at the end of a 0-minute call (the administrator can set it up) without weighing it.

The guard security

Security inspection of the door guard, the door guard will conduct safety inspection to the driver who will enter the factory. The driver will use IC card to store inflammable and explosive products such as mobile phone and smoke into the storage cabinet to ensure the safety of the tank area. The driver leaves the factory to brush IC card to get personal goods.

Access control to verify

Access control verification is a technology that our company optimizes management according to field oil loading cases and years of practical experience. It is a key technology of intelligent storage and transportation vehicle loading system to equip R FID card readers on the basis of original cameras to ensure more accurate vehicle information and enhance identification efficiency. When the vehicle enters the factory, the access control verification passes the double verification of R FID card reader and vehicle number recognition camera, and is transmitted to the data center for comparison. After the correctness, the road lock is opened. At the same time, the license plate number is marked in the system, indicating that the vehicle has arrived. When the vehicle passes through the large door to feel the ground, the road lock falls automatically. Double verification to prevent cheating.

Self-service measurement system

Self-measuring system is also known as self-weighing management system, which can realize the online weighing of more than one vehicle. The same vehicle can be weighed in different vehicle scales with different tare and gross weights. In the process of weighing, automatic and reliable collection, automatic discrimination, automatic command, automatic processing and automatic control of measurement data are realized, and the disadvantages and working intensity brought by manual operation are minimized, and the informatization and automation degree of the system are improved.

Advantages of automatic measurement

High speed of information acquisition: the whole system can achieve fast and accurate weighing.

High efficiency: when the driver weighs, the operator does not have to enter manually and swipe card to confirm information.

Automatic reading of data is adopted. All weighing vehicles are automatically recorded by computer, recording data automatically, verifying and eliminating manual intervention.

The electronic label of the uhf automatic identification system is adopted to provide the only immutable ID number in the world, which fundamentally eliminates duplication, forgery and cheating.

Transaction time is long: the electronic tag adopts passive technology without maintenance and has a long service life. Generally, it can be used for 10 years without damage.

Two - way overbalanced intelligent weighing

The intelligent weighing system ultimately serves the production of the enterprise and creates benefits for the enterprise

Dual verification: vehicle identification camera and RFID reader verify simultaneous vehicle information

It is possible to avoid getting a full pound without infrared radiation

Installing human scale in the weighing room prevents the driver from cheating

Iv. Quantitative loading system

Quantitative loading system is a part of intelligent storage, transportation and loading system, which is designed for the control of production process and the requirement of information construction of oil refinery, oil depot, dangerous goods warehouse, etc. System USES function in dispersing, task, disperse risk and the management of centralized model, using IC card via "one card" way integrated electronic, network, explosion-proof, such as radio frequency identification technology, which will be quantitative loading system and IC card door forbidden system is an organic whole repeatedly, to realize the user make out an invoice, enter the reservoir area, automatic loading such as production management process automation, guarantee the production and management of each link information transmission efficiency, reduce the human error, improve production efficiency and facilitate the vehicle management. The field instruments and equipment all adopt explosion-proof structure and can be installed in the explosion-proof I and II areas. The quantitative loading system includes quantitative loading controller, explosion-proof card reader, flow meter, control valve, filter, electrostatic overflow controller, explosion-proof LED display, temperature transmitter, pressure sensor, etc.

Functional features

Quantitative vehicle loading function brush IC card loading, when reaching the set value, automatically stop loading.

The valve continuous control function makes logical control and adjustment of the valve, controls the opening of the field control valve, realizes two or more sections of adjustment, and ensures the safety and accuracy of loading.

Electrostatic protection when the system is not in electrostatic security detection, automatically stop loading

In the process of loading the vehicle with the power off protection function, the accidental power off can keep the effective data intact and the power can be resumed.

Data acquisition function collects flow meter signal, combustible gas alarm signal, electrostatic ground clamp, overflow switch and other signals.

Remote/field mode conversion function is independent of the loading management computer, but it can also communicate through Modbus, TCP/IP, PROFIBU S standard bus and upper computer system

Loading management computer function

1. Function of IC card: according to customer's requirements, the oil distribution information can be written into the IC card. After arriving at the oil distribution site and meeting the loading conditions, the car can be started by directly connecting the brush card, which is convenient, fast and convenient for information collection and transmission

2. Authority function: there are two levels of authority, which are set in all aspects in the management, control and data layers, and operate the system with the rights that should be allocated independently.

3. Screen display function: screen display score display screen, process flow chart screen, equipment status display screen, trend curve record display screen, alarm information summary screen, etc., the screen display is intuitive, bright color, easy to operate, and the main part adopts dynamic display.

4. Interlock function: stop loading automatically when static electricity and overflow alarm signals are detected, and interlock controls stop pump and close valve, accompanied by sound and light alarm.

5. Quantitative function: it is the core function of each crane position. After the loading condition is satisfied and the loading quantity is set, press the start button, and the system will open the valve and pump in a more set order and start loading. When the preset amount is reached, the system closes the valve and pump and completes the loading operation.

6. Real-time function: collect vehicle loading data in real time, and set quantitative and instantaneous flow rate for detection and display. Data of loading amount, temperature, density and pressure are processed and stored in real time.

7. Log function: record the system operation log and alarm log, query, export, print and cannot be deleted.

8. Report function: customized daily, weekly, monthly, quarterly and annual reports based on user requirements, and formed analysis reports with various graphics, with export and printing functions.

9. Network function: database login interface, enabling the software system of the defender to access the company domain network or In te rn e t.